For Heat-sensitive, Heat-sensitive or High filler material, KTE/SE series Two Stage Extruders are designed for such processes. Twin screw extruder provides mixing and dispersion without over-shear. Low speed single screw extruder provides sufficient cooling and pressure.

SE series Two stage single screw extruder is suitable for high water content (about 10%of water), dirty and light waste plastic recycling material, Granule form uniformly, Extruder capacity stable and high output. The extruder system can be arranged in one -shaped or L type. The main and sub extruder are equipped with large screen changer, which can effectively filter the impurities. And final granules ae full and gloss.

KTE/SE Two Stage extruder line parameters:

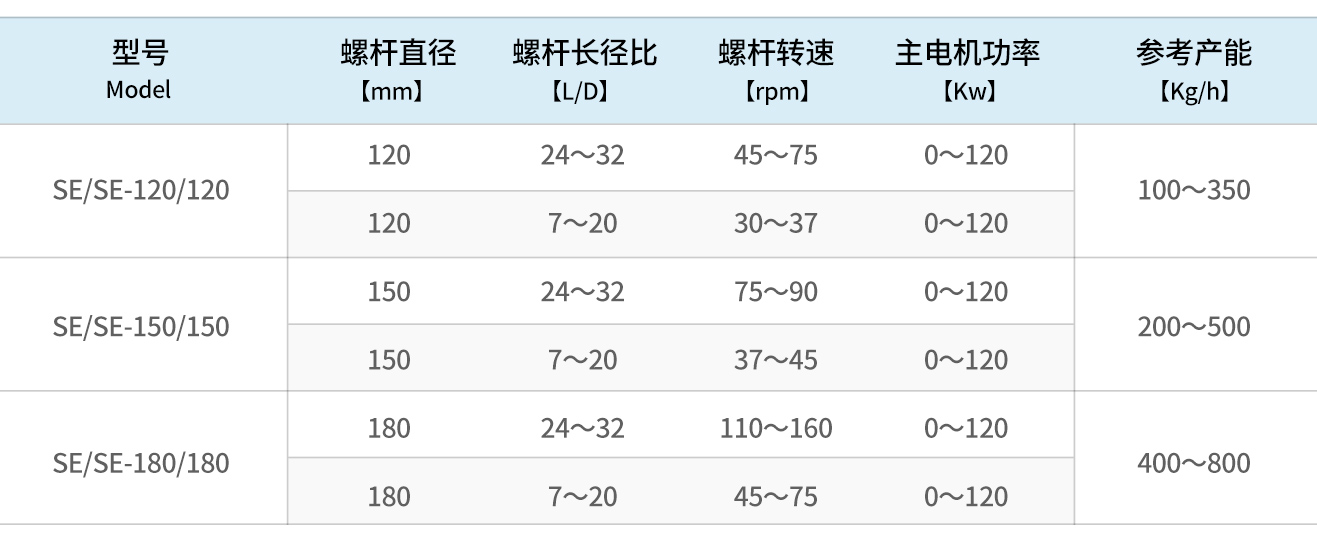

SE/SE Two Stage Single screw extruder line parameters:

KTE/SE Two Stage extruder:

1) PVC compounding for cable;

2) Wood and plastic compounding;

3) EVA compounding with foaming agent or cross-link additives

4) XLPE for cable or PEX pipes

5) High concentration carbon black Masterbatch

SE/SE Two Stage Single screw extruder:

1) Film recycling

2) Waste cloth/silk recycling

3) Soft, hard PVC recycling

4) PP/PE and other crushed flake materials recycling

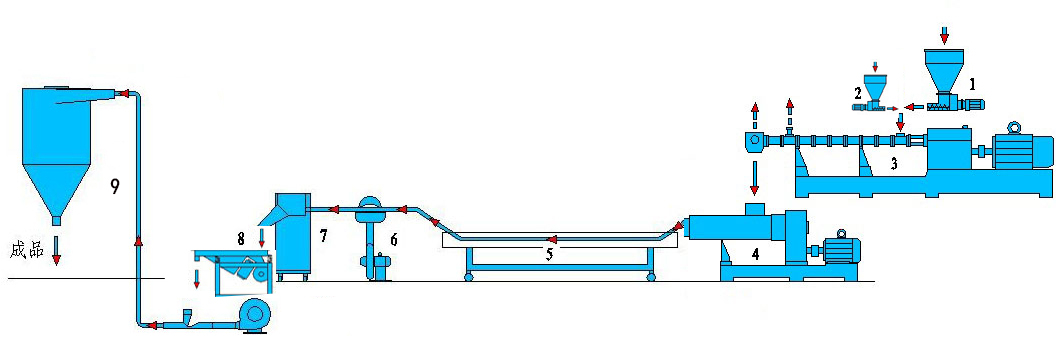

KTE/SE Series:

Water-cooling strands:

1.Main feeder | 2.Side feeder | 3.Twin screw extruder |

4.Single screw extruder | 5.Water tank | 6.Air Knife |

7.Pelletizer | 8.Vibrating sieve | 9.Product silo |

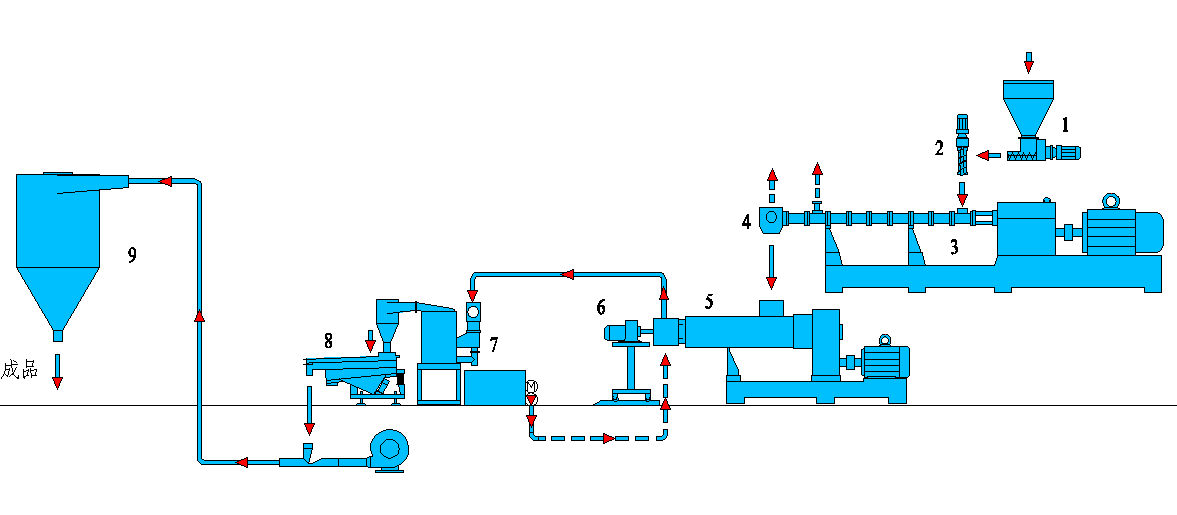

Water-ring hot cut:

1.High speed mixer | 2.Spiral loader | 3.Main feeder |

4.Twin screw extruder | 5.Single screw extruder | 6.Water-ring hot cutter |

7.Dewaterer machine | 8.Vibrating sieve | 9.Product silo |

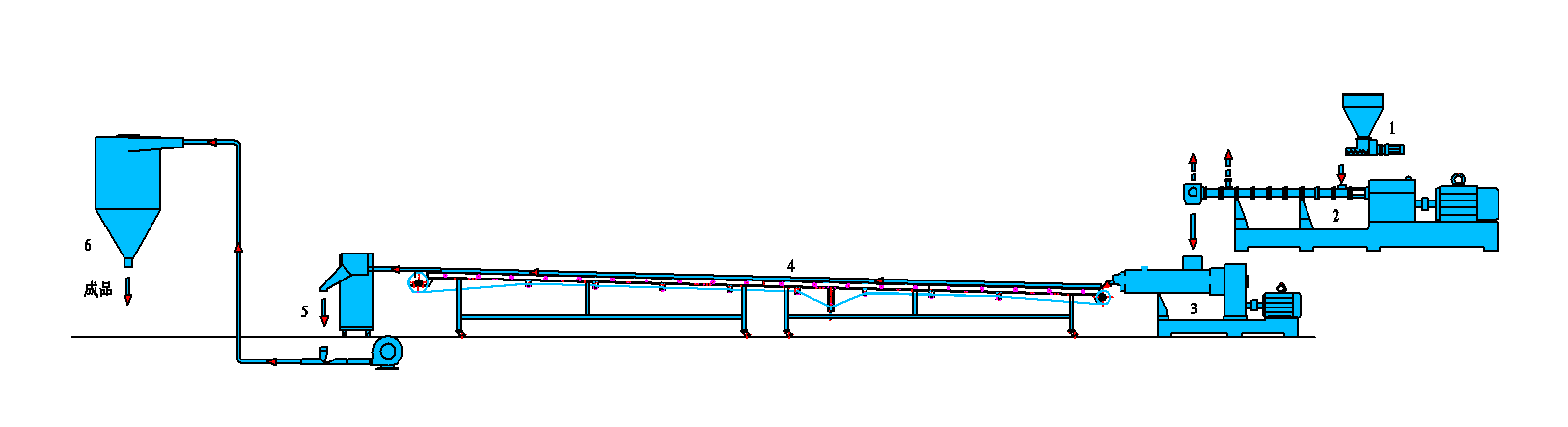

Air-cooling strands:

1.Main feeder | 2.Twin screw extruder | 3.Single screw extruder |

4.Belt conveyor | 5.Pelletizer | 6.Product silo |

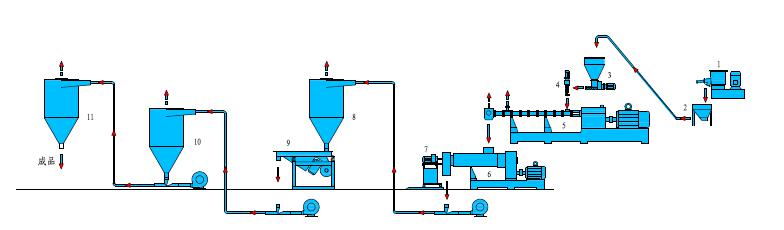

Air-cooling hot cut:

1.High speed mixer | 2.Spiral loader | 3.Main feeder | 4.Force feeder | 5.Twin screw extruder | 6.Single screw extruder |

7.Air-cooling hot cutter | 8.Cyclone | 9.Vibrating sieve | 10.Cyclone | 11.Product silo | |

Underwater Pelletizer:

1.Main feeder | 2.Force feeder | 3.Twin screw extruder |

4.Extrude side | 5.Single screw extruder | 6.Underwater pelletizer |

7.Dewaterer machine | 8.Vibraing sieve | 9.Product silo |

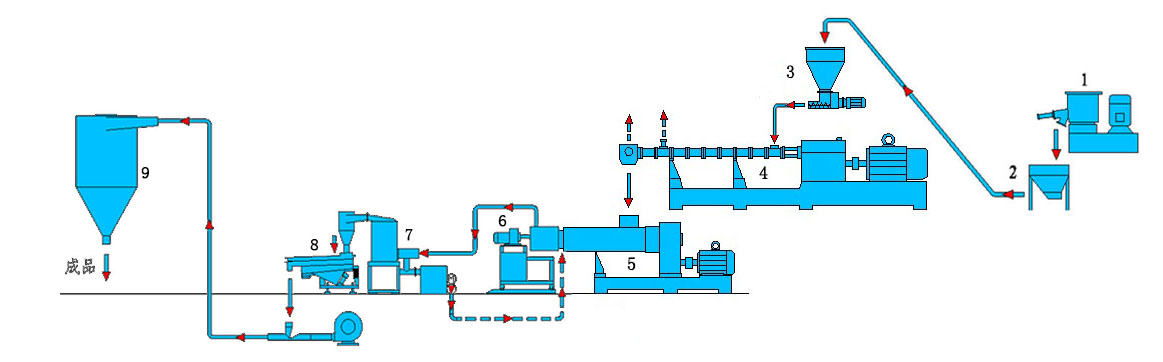

SE/SE Seires:

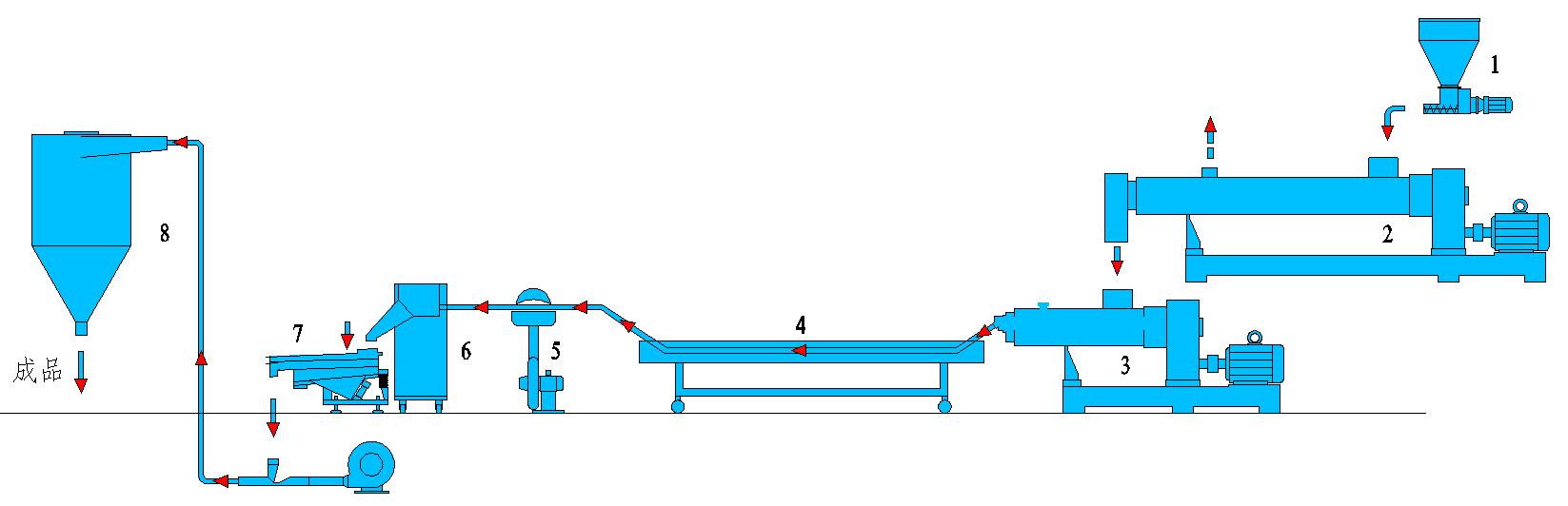

Water-cooling strands:

1.High speed mixer | 2.Single screw extruder | 3.Single screw extruder | 4.Water tank |

5.Air knife | 6.Pelletizer | 7.Vibrating sieve | 8.Product silo |

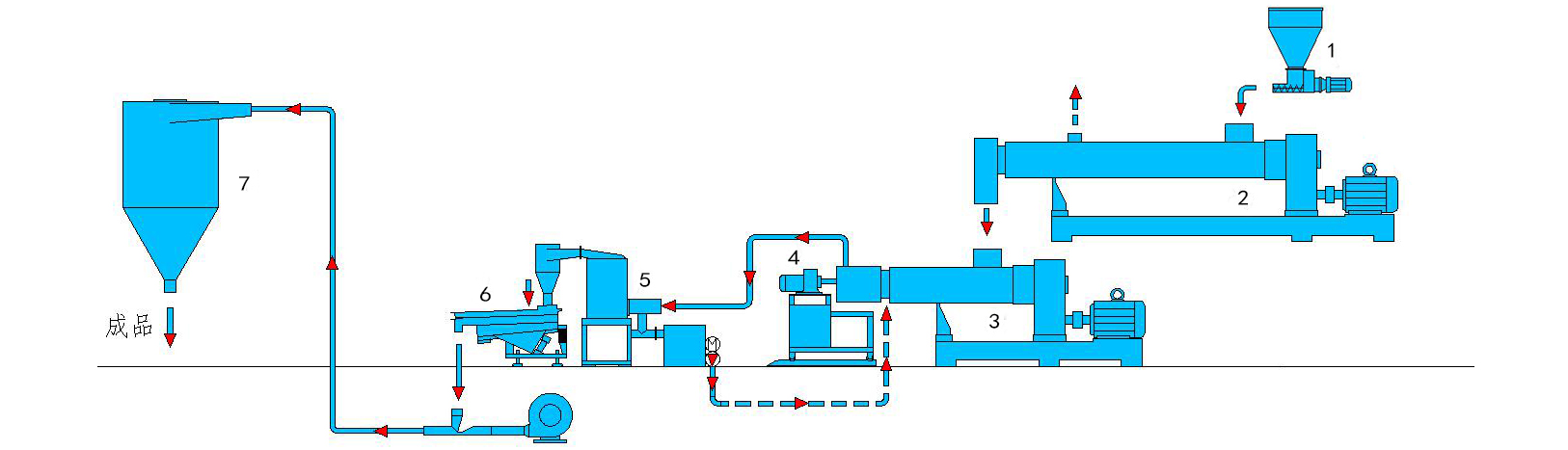

Water-ring hot cut:

1.Main feeder | 2.Single screw extruder | 3.Single screw extruder | 4.Water-ring hot cutter |

5.Dewaterer machine | 6.Vibrating sieve | 7.Product silo | |

*

*