The Filling Master Batch Refers to That in the Process of Plastic Processing and Molding, for the Convenience of Operation, All Kinds of Additives, Fillers and a Small Amount of Carrier Resin Are Mixed and Blended First, and the Prepared Particles and Powders Are Called Master Batch.

Masterbatch is Composed of Carrier Resin, Filler and Various Additives. the Limit of Additives or Filler Content in the Masterbatch is Several Times to Ten Times Higher Than That in the Actual Plastic Products. in the Process of Molding, the Proportion of Masterbatch and Matrix Resin Must Be Adjusted According to the Content of Relevant Components in Masterbatch and the Amount to Be Added in Actual Products.

Masterbatches Can Usually Be Divided into Ordinary Filling Masterbatches (hereinafter Referred to As Filling Masterbatches) and Functional Masterbatches, Such As Color Masterbatches, Anti Fog Masterbatches, Etc. the Main Component of Filling Masterbatch is Filler, Which is Mainly Used for the Processing and Molding of Polyolefin (polyethylene and Polypropylene), Also Known As Polyolefin Filling Masterbatch.

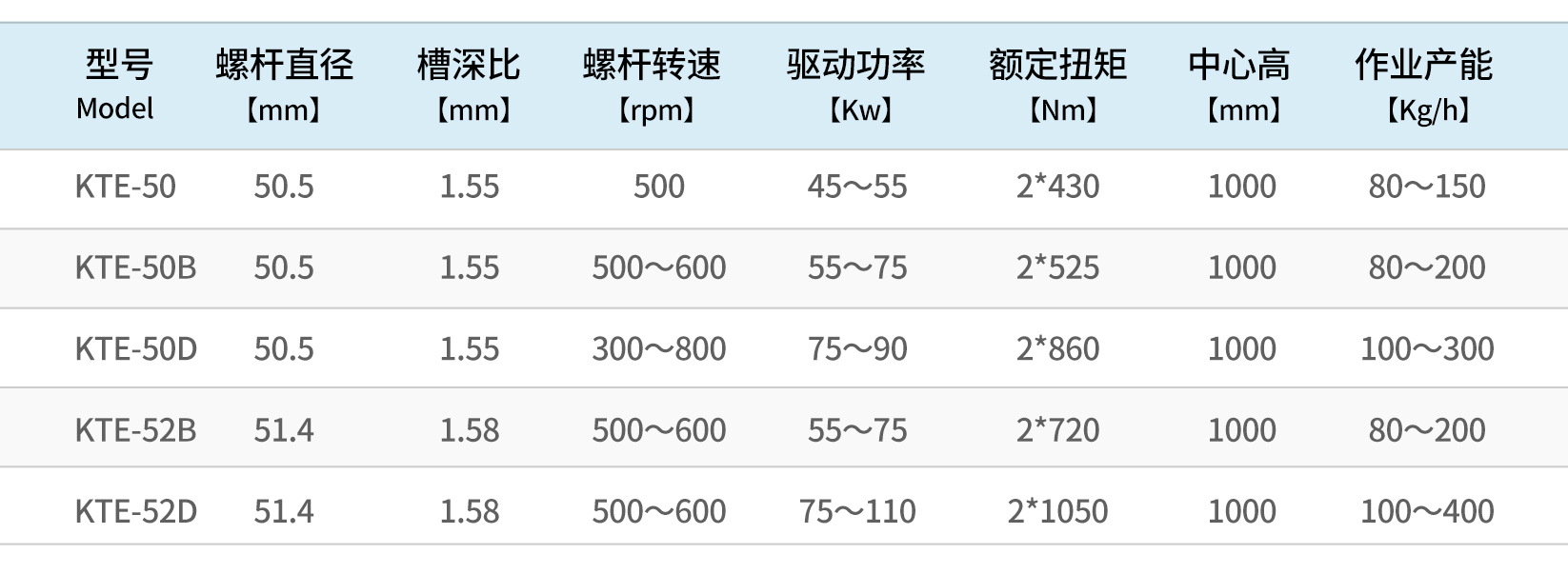

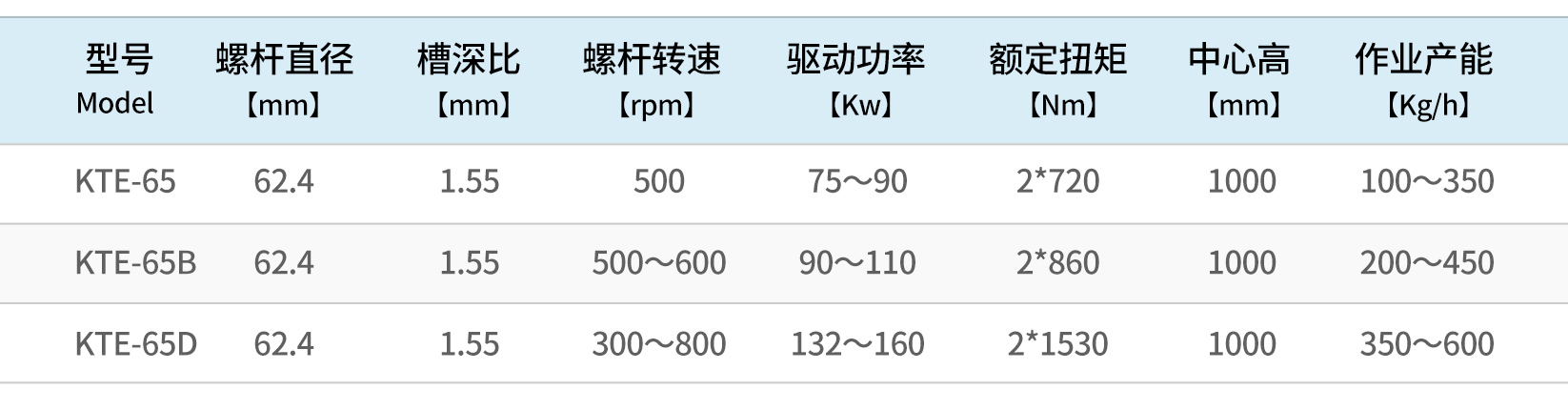

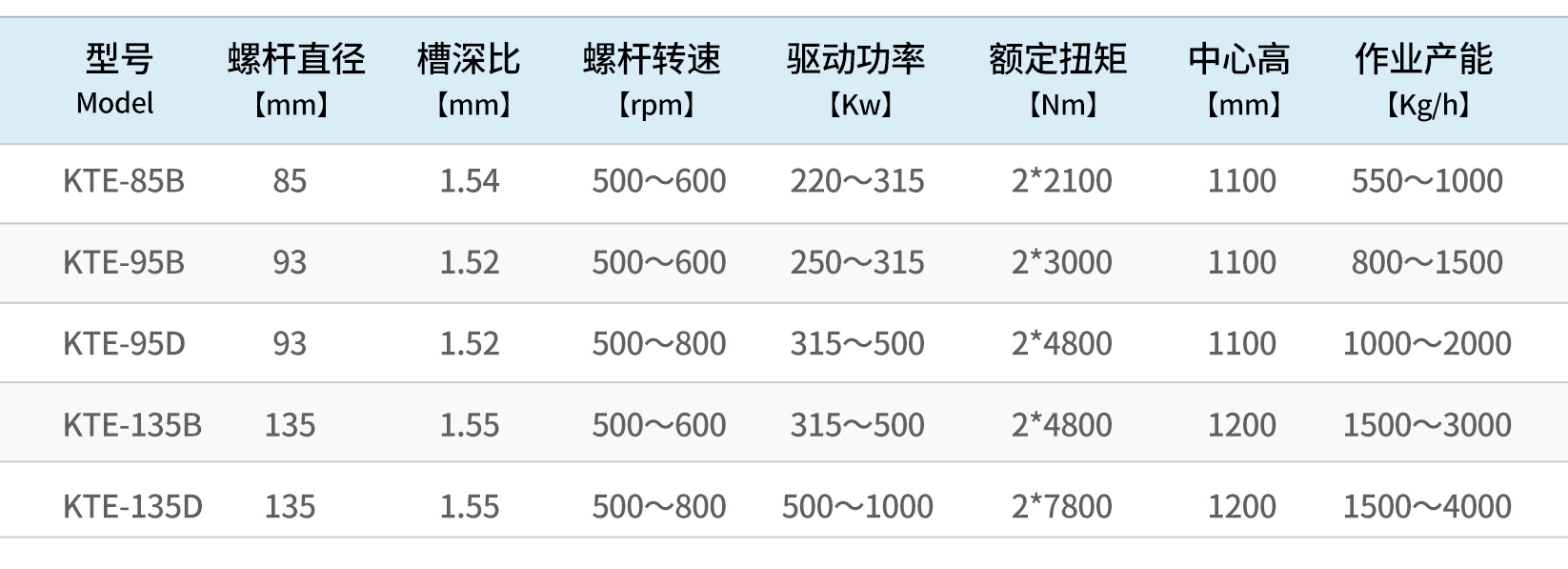

We Can Customize the Filling Masterbatch Granulator According to Your Requirements, Output, Formula and Purpose.

1) Medical and Health Care

2) Special Materials for Sheet / Plate / Pipe

3) Packaging

4) Household, Etc

*

*