As the solution provider, we create real added value and secure the competitive edge of our customers.

Machine Running to Countries worldwide

Installed compounding machines & extruders worldwide

Employees worldwide

Manufacturing Area (M2)

Cable material industry

Cable material industryCable material industryCable material industry

Engineering Plastic

Engineering Plastics Generally Refer to Plastic Materials That Can Withstand Mechanical Stress As Structural Materials and Can Be Used in a Wide Temperature Range and Harsh Chemical and Physical Environments. Engineering Plastics Can Be Divided into General Engineering Plastics and Special Engineering Plastics.

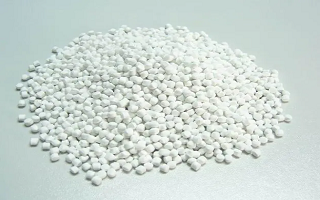

Color Masterbatch

There Are Three Types of Color Masterbatch: 1) Mono Color Masterbatch or SPC (Single Pigment Concentrate): Polymer Compounding with One Single Pigment and Mostly Without the Wax and Additive 2) Tailor-made Masterbatch or Custom Coloring: Mixing Different Mono Color Masterbatch Pellets to Get the Color the Customer Wants 3) Customized Masterbatch: Mix Polymer and Several Pigment and Additives

Filler Masterbatch

The Filling Master Batch Refers to That in the Process of Plastic Processing and Molding, for the Convenience of Operation, All Kinds of Additives, Fillers and a Small Amount of Carrier Resin Are Mixed and Blended First, and the Prepared Particles and Powders Are Called Master Batch.